1.Food Process & Storage

We at Foster Dynamics, are unsurpassed by our knowledge and passion for working with the Food Processing Industry. We are uniquely qualified to construct your new facility or improve your existing one; in the fact that we have, and continue to, work with all the different markets.This includes Poultry, Fish, Beef and Dairy, Produce and Confections worldwide.

Foster Dynamics is aware of the every changing need for quality control during the food preparation process, which is why we continue to educate ourselves on changing international standards. We want you, our client, to feel and know that your facility is designed and constructed to the highest food-grade quality possible!

Give us a call and let our experienced experts help with your next project!

2.Large Refrigerated Warehouses

Foster Dynamics knows the importance of proper refrigerated areas, and warehouses are no exception. We believe that the refrigerated warehouse encompasses the basic fundamentals of cold storage. These spaces are the beginnings and ends of most food processing and distribution facilities.!

For large and complicated cold storage facilities we work in partnership with country's leading manufacturers of metal buildings.This gives us exclusive erudition of warehouse design and engineering. Combined that knowledge with our accredited refrigeration skills and service, and you have an incredible amalgamation of ingenuity.

Whether you have a need for pallet rack storage, refrigerated shipping docks or a new cold storage and distibution warehouse, Cold Storage has you covered. Give us a call and let our design professionals unleash the potential of your warehouse!

3.Walk-in Coolers & Freezers

These units are the humble beginnings of Foster Dynamics and continues to be a major focus of our market segment. For over 65 years, Foster has been selling, manufacturing, distributing and installing cam lock Style Walk-in Coolers and Freezers worldwide.

Cold Storage has been instrumental in advancing the design and construction methods for Walk-in Units. We continue to refine our manufacturing process and keep most refrigeration equipment for Walk-in Units in-stock, all to shorten the turn around time of your order. We have become so deeply efficient in this process that we have been able to provide and install most Walk-in units within days of the order!

4.Biotech & Pharmaceutical

This is a unique market segment with specialized requirements and specifications. Fortunately,

Foster Dynamics has innate knowledge of this industry. We have been providing refrigerated and heated

walk-in units for this market ever since we began manufacturing insulated panels.

Foster Dynamics can provide;

. Environmental Test Chambers

. Pharmaceutical Cold Storage Rooms

. Accelerated Weather Testing Vaults

operate at temperatures as low as -40°Celsius (-40°F) and as high as +85° Celsius (+185°F).

Give us a call and lege room!

4.Biotech & Pharmaceutical

This is a unique market segment with specialized requirements and specifications. Fortunately,

Foster Dynamics has innate knowledge of this industry. We have been providing refrigerated and heated

walk-in units for this market ever since we began manufacturing insulated panels.

Foster Dynamics can provide;

. Environmental Test Chambers

. Pharmaceutical Cold Storage Rooms

. Accelerated Weather Testing Vaults

operate at temperatures as low as -40°Celsius (-40°F) and as high as +85° Celsius (+185°F).

Give us a call and lege room!

5.Refrigerated Sea Water System

(We provide best refrigerated sea water system in Pakistan Introduction)

Introduction

Most fishermen use ice (icing) as a fish preservative for fresh fish products and use the freezer as frozen fish product. Handling of fish catchesbr in the sea on fishing boats is the first stage that determines the quality offish that directly impact on the selling price. RSW to overcome the weakness of the use of ice in the fish preservation on the ship. It’s technique of cooling and preserving fish by inserting fish into a hold or chamber containing cold sea air temperature of about -5 C which is cooled by a refrigeration system. RSW system is the technology which is successfully used many countries especially Canada and Nordic Countries. It is the only system by which we can get the perfect water temperature control to get the fish quality maintained.

Prologue

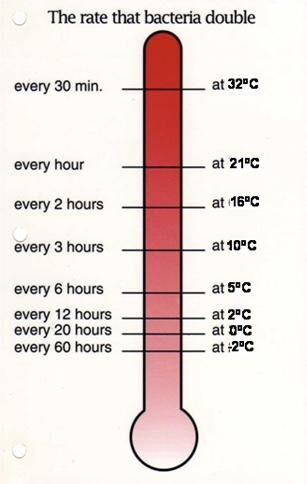

All types of sea foods are perishable. Once bacteria action starts, as shown in Fig. 1, it cannot reverse; at best stopped from further deterioration, it is therefore imperative that preservation starts at the very beginning. It is said that “Fish of Pakistan is one of the Best in the World as long as it is in water”, the moment it is on deck deterioration starts from the way it is handled and then preserved. During the 1970’s FAO had passed a verdict that Pakistani wooden fishing trawlers can never be made hygienic. In the 70 years of history, fishermen being conservative in nature, local efforts have achieved half-baked lining and insulation of holds, albeit still using the same methods of stacking and manual handling. The result is encouraging as now to some degree B grade is achieved in some percentage of catch. Grade A quantities are small and still out of reach in most cases.

All types of sea foods are perishable. Once bacteria action starts, as shown in Fig. 1, it cannot reverse; at best stopped from further deterioration, it is therefore imperative that preservation starts at the very beginning. It is said that “Fish of Pakistan is one of the Best in the World as long as it is in water”, the moment it is on deck deterioration starts from the way it is handled and then preserved. During the 1970’s FAO had passed a verdict that Pakistani wooden fishing trawlers can never be made hygienic. In the 70 years of history, fishermen being conservative in nature, local efforts have achieved half-baked lining and insulation of holds, albeit still using the same methods of stacking and manual handling. The result is encouraging as now to some degree B grade is achieved in some percentage of catch. Grade A quantities are small and still out of reach in most cases.

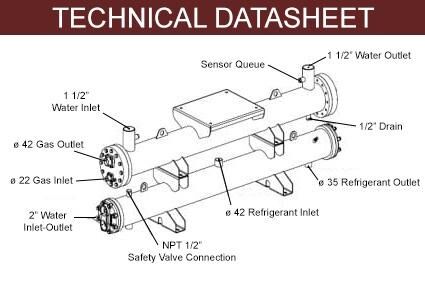

Working of Refrigerated Sea Water System

The process of getting cold water into the fish hold starts from suction from sea, passing this water through the heat exchanger of a refrigerated system where in expanded cool gas is passed on one side and sea water on the other. This water is pumped into the fish holds from the top and sprayed evenly over the entire area.

The process of getting cold water into the fish hold starts from suction from sea, passing this water through the heat exchanger of a refrigerated system where in expanded cool gas is passed on one side and sea water on the other. This water is pumped into the fish holds from the top and sprayed evenly over the entire area.

Once the water had reached the desired level, it is recirculated through bottom suction to obtain the desired temperature. Depending on the quantity of catch, the water level and temperature are maintained for optimum results. Generally, this translates to thirty percent water and seventy percent catch. It is noteworthy that the normal capacity of fish holds is around 45 tons of catch

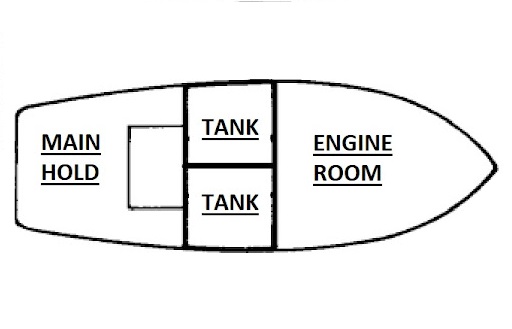

Refrigerated Sea Water System Storage Tanks

RSW tanks are normally constructed adjacent to one another spanning the width (beam) of the vessel. There are usually 2, 3, 6, etc. storage tanks on board a single vessel. The storage tanks are normally loaded to a capacity of approximately 80% fish and 20% water, depending on the type of fish. The tanks must be properly insulated from the hull, deck heads, machinery- and accommodation spaces to limit the possibility of heat ingress as much as possible. Furthermore the tanks must be equipped with over-flow and equalizing pipes. It is essential that the interior surfaces of the tanks have a smooth finish, with no obstructions or sharp edges.

Disadvantages of Using Ice for Fishing

- High cost of ice blocks./li>

- Unhygienic water used in making of ice pollutes the fishes.

- Sharp corners of crushed ice pierces the skin of fishes causing bacterial degeneration and loss of proteins.

- Low quality of fishes due to delayed handling.

- Low cooling efficiency for catches as compared to RSW System.

- Stacked fishes stresses the lowest layer.

- Stacked fishes stresses the lowest layer.

- Ice may or may not be utilized which leads to waste of ice and money.